Air Conditioning Maintenance

Most car owners don't service their air conditioning until after it fails. Maintaining your car or truck air conditioning system means that you always have enough refrigerant to properly do the job. Small leaks in the air conditioning system allow the refrigerant to escape and the system can't cool the air as well.

Along with the refrigerant, a special oil circulates in the system. The oil lubricates air conditioning components, and keeps the seals resilient. Low refrigerant and lubricating oil means that the air conditioning parts will wear out prematurely, and we all know that air conditioning repairs can sometimes be costly.

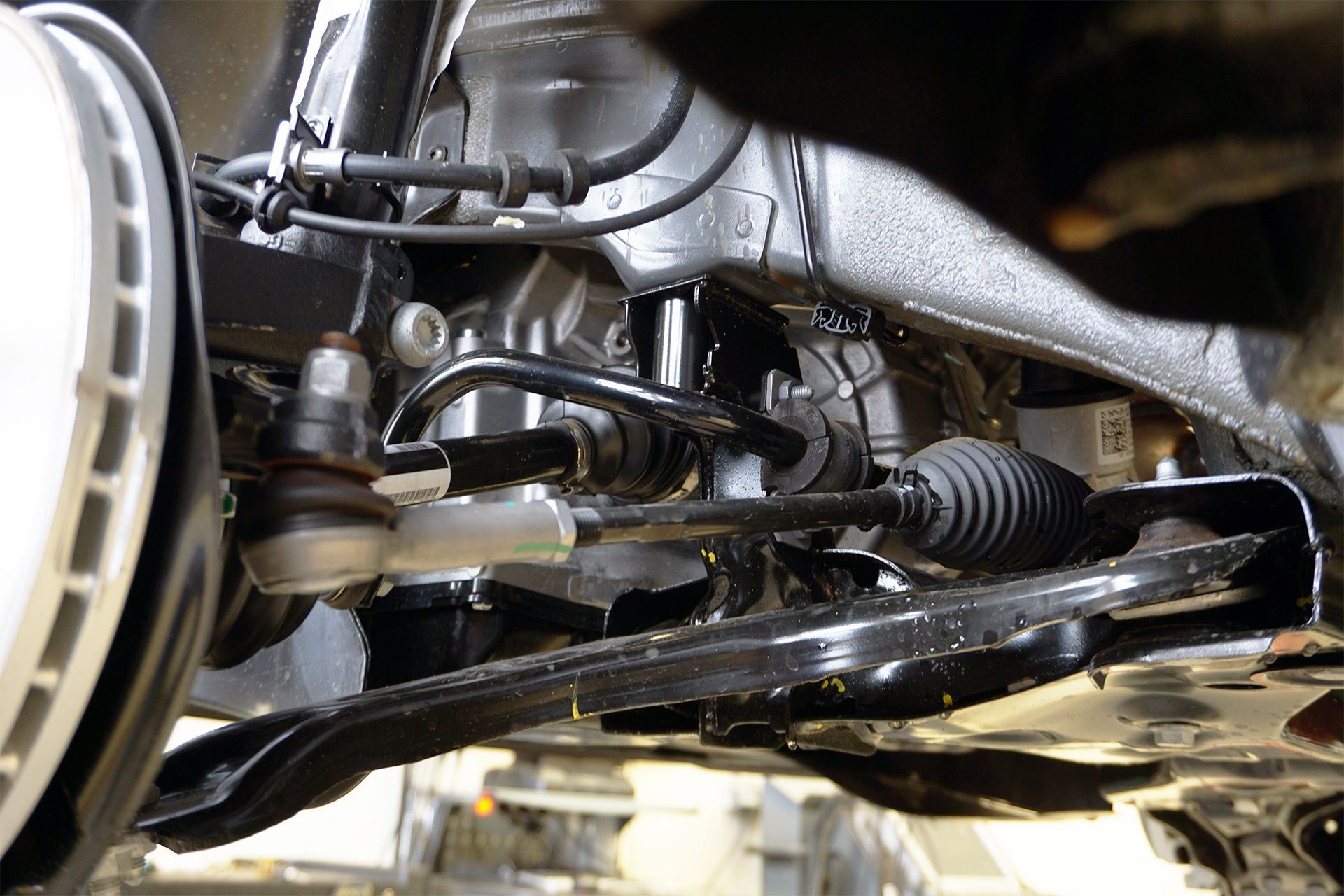

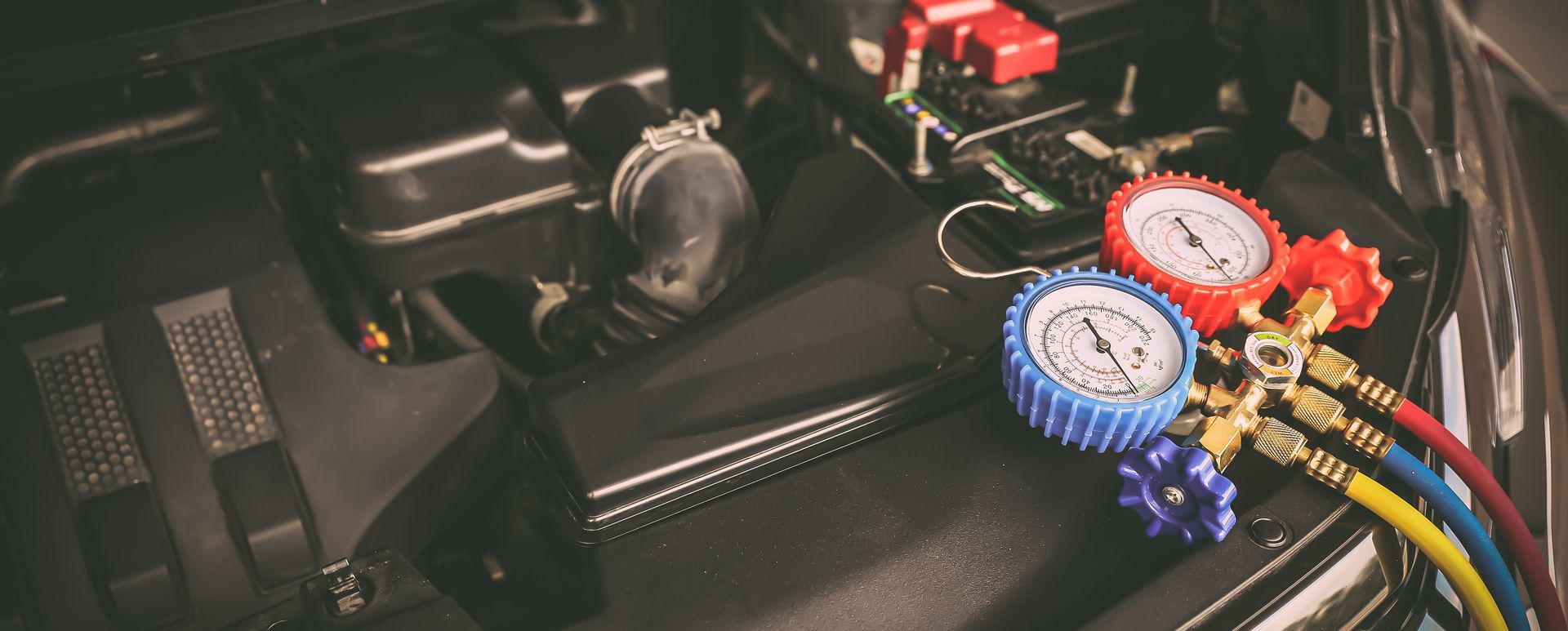

Air conditioning service at our shop starts with a visual inspection of the components for signs of damage or leaks. The compressor is driven by a belt from the engine - most often the serpentine belt - so it is inspected for cracks or wear.

The air conditioning compressor and other components are checked for proper operation by ASE Certified Service Center Technicians. Then comes the leak test. If a leak is detected, often in a hose or connection, it's repaired and the system is retested. Our mechanics will also perform a temperature drop test.

Air Conditioning Service and Repair

Today's vehicle A/C systems can lose 5% of their refrigerant per year causing the system to become inefficient. Another thing to remember is the A/C system is used all year long; every time the defroster is used the A/C system is activated to assist in removing the moisture from inside the vehicle which can defog windows much faster than non-A/C-equipped vehicles.

It is recommended that modern A/C systems be tested annually to ensure peak performance. Schedule an appointment with one of our factory trained professionals and let us make sure your A/C system is running efficiently.

At Begley Auto Repair, we have the equipment available to diagnose the latest computerized components.

Below is a brief explanation of the major components that makes these A/C systems work so well:

Compressor: The compressor is a belt-driven device that compresses refrigerant gas and transfers it into the condenser. The compressor is the core of your vehicles air conditioning system.

Condenser: The condenser's primary function is to cool the refrigerant. The condenser dissipates heat released by compressed gases and condenses them into high pressure liquids.

Receiver (Drier): The receiver is a metal container that serves as a storage receptacle for the refrigerant - also known as a drier because it absorbs moisture from the refrigerant and filters out harmful debris and acids. You should change your drier ever 3 - 4 years to ensure quality filtration and prevent any chemical damage.

Orifice Tube/Expansion Valve: The orifice tube, also known as the expansion valve, is a controlling mechanism that regulates refrigerant flow throughout the system. It also converts high pressure liquid refrigerant (from the condenser) into low pressure liquid, so that it can enter the evaporator.

Evaporator: The evaporator removes heat from the inside of your vehicle. The evaporator allows the refrigerant to absorb heat, causing it to boil and change into a vapor. When this occurs, the vapor leaves the evaporator through the compressor, cooling your car and reducing humidity. The evaporator houses the most refrigerant in the heat transfer process and harmful acids can corrode it. The corrosion typically damages the evaporator beyond repair.